What Equipment We USe

To be the best, you need to work with the best.

We think of it bit like a high performing sports car. You can’t use the cheapest parts or the same as everyone else if you want to achieve results that your competition can’t and the same goes for our scaffolding equipment.

We won’t take risks with cheap Chinese scaffolding systems with no quality assurance, testing or engineering data and neither should you.

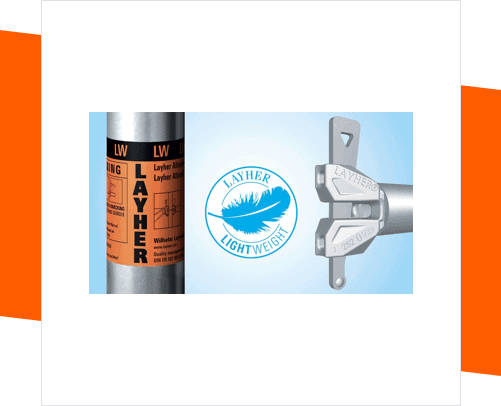

Exclusively using the Layher Range of Scaffolding systems, you can rely on us to support our best possible service by using the best possible scaffolding system. The Layher range of scaffolding components has changed the way scaffolding is used and achieving outcomes that traditional system could not dream of.

Some of the key difference between our scaffolding products and the competitions:

Lighter, Stronger, Faster, Engineering

This is one of the most common misconceptions throughout the industry and YES the Layher Scaffolding System is more expensive than traditional scaffolding systems to purchase but you cannot simply compare the two thinking they are the same thing. Their levels of performance cannot be compared and it is important to understand the differences between the two systems.

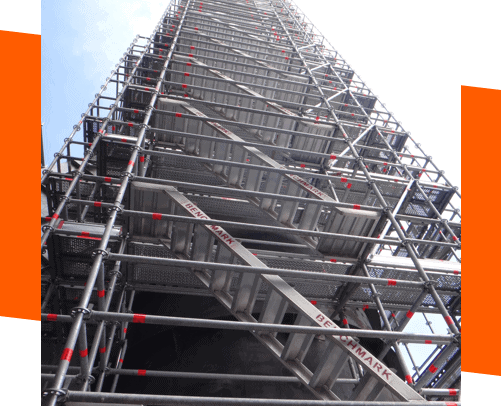

To give you some context take the high rise building image for example:

Yes, the scaffolding will be installed faster, the working platforms will be stronger, less components will be required and the entire project will look much neater but extra cost of the equipment hire will offset any labour savings. For this project you will not receive the full benefit of using a premium product because you simply do not require the extra performance.

But in this case, traditional scaffolding systems simply can’t compete and the cost savings are incredible. Most traditional scaffolding system can only build to a max height of 45m or require significant reinforcing to prevent the vertical supports from buckling under the pressure.

As you can see the cost saving are significant and the overall result can not be compared.

It is important to understand the capabilities of the Layher Scaffolding System and what it can and can’t do. The system is designed primarily for the industrial market and the performance of the system is not on the same level as traditional scaffolding systems.

Take this circular fuel storage tank for example. Traditional scaffolding systems are only designed to be build in straight lines. You can confirm this by the way the equipment is designed with the only possible connections being located at 90 degrees. The round rosette of the Layher Scaffolding System allows a full 360 degree connection and possibility to turn corners.

This simple cantilever further highlights the performance advantages and cost savings found in the industrial market. The time savings and the ability to complete the cantilever from the safety of the working platform far out weights the cost of hiring the equipment.

The results speak for themselves, but it is the things that you can see that really sets the two system apart. Traditional scaffolding systems are manufactured in China, India and the Middle East and as the market is flooded with so many different manufacturers products, the manufactures need to use the cheapest possible raw products to keep the price as low as possible. Very few (if any) manufacturers provide engineering and test data on the products they sell so the scaffolding contractor is left to work it out for themselves. This is where the Layher Scaffolding Products really shines!

The level of testing and engineering Layher completed before any products leave the showroom can only be compared to that of an aircraft manufacturer. Every piece is tested and measured to ensure the highest standard are met and maintained.

So, what does this mean for you? This mean that we can rely on the engineering and test data to design your scaffolding requirements using the least amount of scaffolding equipment and achieve the best out come for you while keeping our costs to a minimum.

When our life, your life and the life of your workers are relying on the scaffolding equipment doing its job, there is no option but to know the equipment is up to the task.

Sun Metals – Autoclave Flash Vessels

- Cantilever Scaffolding, Encapsulation & Containment, Scaffolding Design, Suspended Scaffolding

SMC Shutdown – Cranable Scaffold Roaster

- Bridging & Large Spans, Cantilever Scaffolding, Marine & Offshore Works, Scaffolding Design, Suspended Scaffolding

QSL – Lucinda Shiploader

- Bridging & Large Spans, Cantilever Scaffolding, Marine & Offshore Works, Scaffolding Design, Suspended Scaffolding

QSL– Fender Chain Replacement

- Bridging & Large Spans, Cantilever Scaffolding, Scaffolding Design, Suspended Scaffolding